TKMicro is the best solution for HVAC/R.

WHY?

- Thanks to a thorough know-how of air-cooled units ThermoKey is able to develop new products and customized solutions in synergy with its customers.

- ThermoKey has invested in a state-of-the-art production process both for small batches and large series production.

PRODUCTION

ThermoKey is a leading company in the production of Microchannel cores in Europe. Cores are used by the main European chiller manufacturers/OEM as well as by ThermoKey inside its air-cooled units.

USE

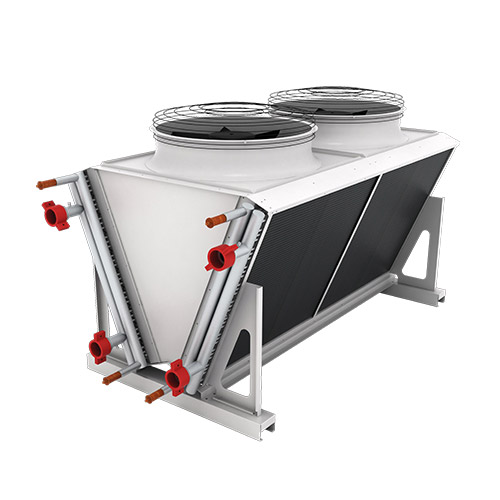

Microchannel cores are used in the remote condensers and also in the chillers as condensing units or liquid coolers (free-cooling) or combined. Specifically in systems as HVAC Chillers, Process Chillers, Data Centre systems, Rooftop systems, Airside Equipements, Food and Beverage and Industrial Process Equipments.

COMPATIBILITY

ThermoKey cores, in the various configurations, are compatible with all standard refrigerants (R410A, R134a, R22, R407C, R404, R507A, R245fa), ammonia (R717), propane (R290), R32 (T5>120ÅãC) up to a maximum working pressure of 45 bar and test pressure of 50 bar and water (R718).

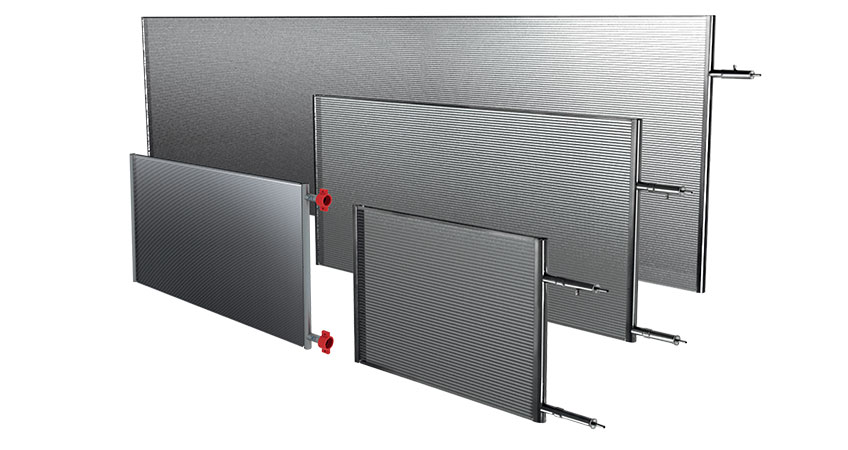

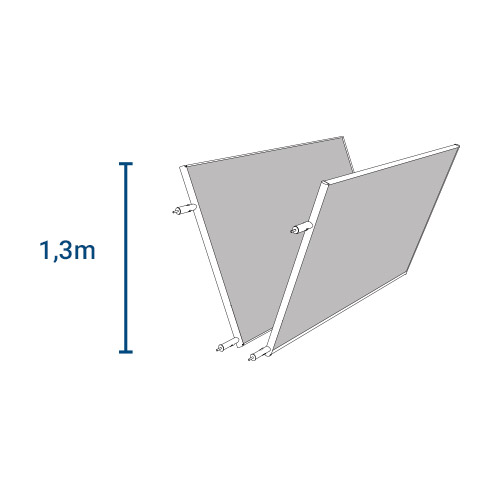

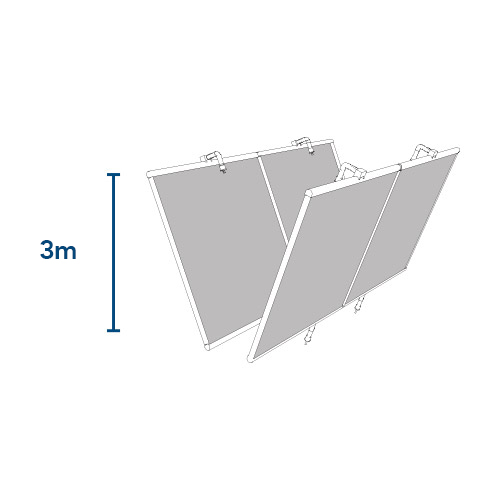

MEASURES

ThermoKey can manufactures cores to fit a wide range of dimensions: length from 500mm to 5400mm and height from 450mm to 1300mm.

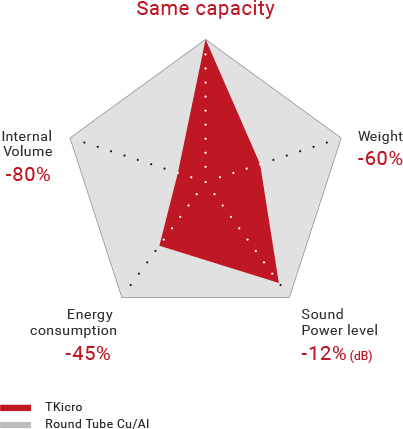

COMPARISON WITH ROUND-TUBE TECHNOLOGY

TKMicro offers great advantage in terms of performances. Compared to a traditional tube and fin coil with the same capacity TKMicro offers great advantages in terms of performance:

Condensing Unit

LESS WEIGHT AND REDUCED THICKNESS

60% less weight with the same capacity.

LESS REFRIGERANT CHARGE

80% less internal volume.

ENERGY CONSUMPTION

45% less energy consumptions thanks to lower pressure drops on the air side.

SOUND POWER LEVEL

12% less sound power level thanks to a reduced thickness of the core compared to a 3/4 row tube and fin coil.

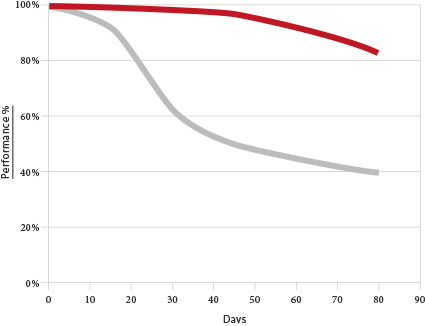

More reliability

CONSTANT PERFORMANCE OVER TIME EVEN IN THE MOST AGGRESSIVE ENVIRONMENTS. COMPARISON BETWEEN ROUND TUBE TECHNOLOGY AND TKMICRO

The accurate choice of the materials supplied by the best manufacturers, the control over the manufacturing process and the attention given to every single detail make TKMicro the most reliable core in the market. TKMicro has brillantly performed in the SWAAT Test (ASTM G85-02 norm) resisting over 80 days.

Condenser

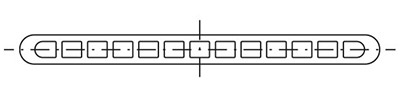

HEADER

D-shape header

- For its most demanding customers ThermoKey also provides the D-shape header with 3mm wall thickness. The D-shape has lower pressure drops and is specifically designed for chiller manufacturers.

- Best distribution of refrigerant inside the core.

- Lower pressure drops.

- Best performance of the core.

CONDENSER MULTI PORT EXTRUDED (MPE)

TKMicro25 condensers: 25mm width*

The best compromise between performance and lightness. Microchannel cores with a 25mm tube have a slightly higher capacity than a traditional tube and fin 3 Row 3/8” tube coil.

CONDENSER MULTI PORT EXTRUDED (MPE)

TKMicro32 condensers: 32mm width*

Ideal for the low pressure drops and maximum heat transfer. Particularly suitable for application with high air flow rate. Microchannel cores with a 32mm tube have clearly a higher performance than a traditional tube and fin 4 Row 3/8” tube coil.

(*) Up to 45 Bar Ps

Technology

THERMOKEY MICROCHANNEL

TECHNOLOGY

ThermoKey has chosen the top class materials available to ensure the maximum quality for its TKMicro technology. All core details are developed together with the best suppliers in the market in order to answer to the specific requirements of the HVAC/R market.

MULTI PORT EXTRUDED (MPE)

MPE tubes allow the best heat transfer with the minimum dimensions. We provide three different types of MPE tubes to better meet the needs of our customers.

FIN

Using Finite Element Analysis (FEA) technique and our Wind Tunnel facility, we have optimized louvered angles, fin pitch and the number of louvers in order to achieve minimum air side pressure drops and, at the same time, maximize the air heat transfer.

We produce fins that fit both the 32mm tube and the 25mm tube. The brazing process ensures a perfect and permanent contact between tubes and fins

For particularly aggressive environments various types of surface/treatments are available.

How to use TKMicro for HVAC/R

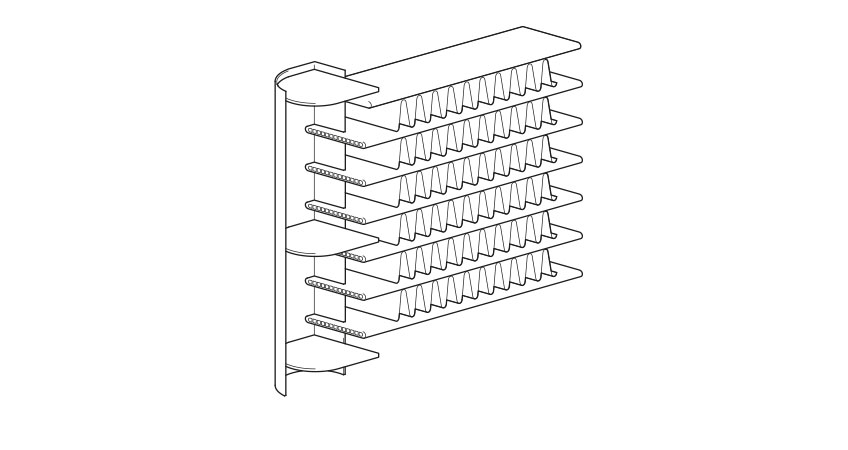

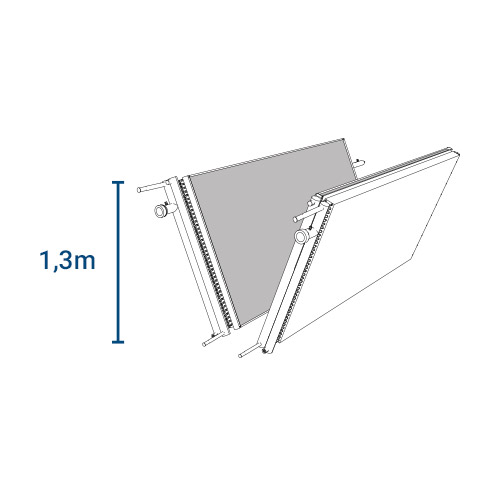

HORIZONTAL MODE

Standard series for condensing e liquid cooling.

VERTICAL MODE

Super low pressure drop designed for condenser

FREE COOLING APPLICATION

Condensing and free cooling avaiable both tube & fin and TKMicro.

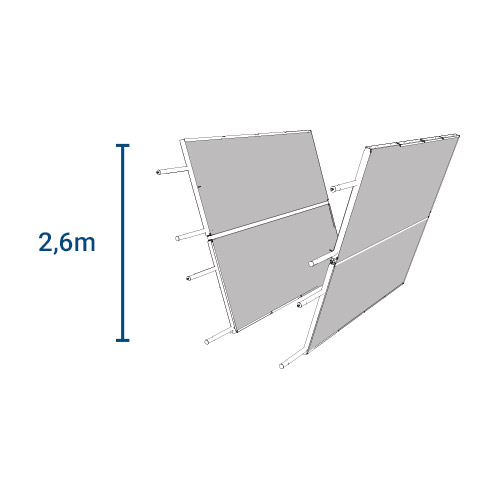

MULTIPLE HORIZONTAL MODE

Maximum performance with the minimum footprint.

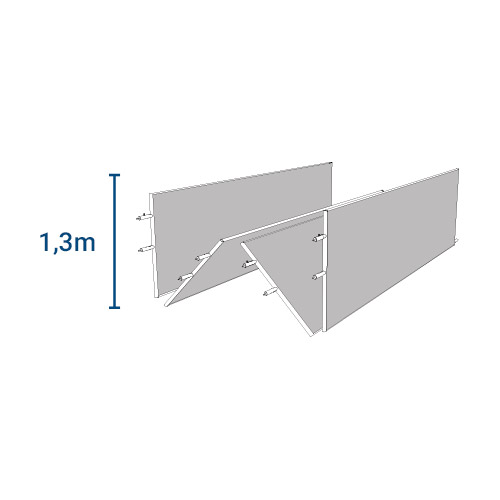

UPSIDEDOWN “M” SHAPE

Specific for chiller manufacturers to maximize the subcooling unit on the four cores.

TKMicro – Research and development

ThermoKey is constantly involved in an ongoing activity to develop new products and solutions.

Every detail is studied to optimize performances.

To guarantee always the best quality our engineers are working on several aspects:

STRUCTURAL CALCULATION

Through FEM analysis we are able to foresee material deformations and work on possible problems before they occur.

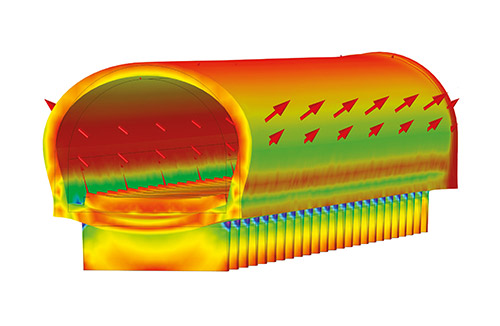

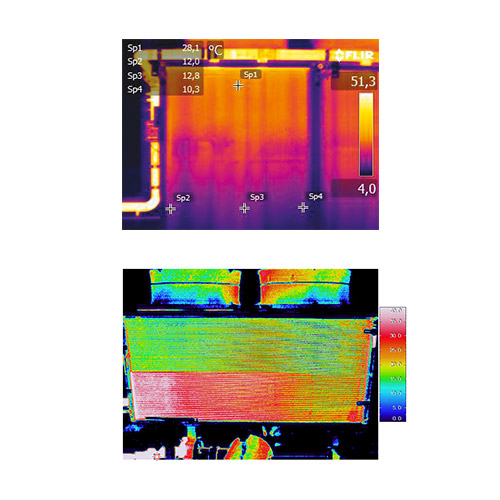

AIR-FLOW SIMULATIONS

The air-flow performance of the TKMicro cores is tested through an especially built Wind Tunnel which is able to reach 22,000 m3/h.

THERMO-FLUID-DYNAMIC ANALYSES

The thermodynamic performance is maybe the most important information for our customers. To obtain always more reliable data we carry out CFD simulations of the fluid distribution inside the heat exchanger and we constantly verify the accuracy.

TKThermalKey

CALCULATION FUNCTION

TKThermalKey is a thermodynamic calculation software developed internally by ThermoKey.

It is used for the selection of microchannels units (remote condensers and liquid coolers).

VERIFY FUNCTION

In the condenser section the user can select the units choosing among 15 different refrigerants.

- Company profile brochure

- TKSmart brochure

- Brochure Microchannel solutions by ThermoKey

- IG manual - General instructions for safe use

- IS manual - Specific use and maintenance instructions

- TC manual - Instruction and technical specifications

- IM manual - Instructions for handling and unpacking