process dualflow unit cooler

ThermoKey process dualflow unit cooler. To prevent heat from being lost and flowing towards the cold room during the defrosting stage and to prevent, while the unit cooler is working, the external drip tray from cooling.

Area of use:

processing rooms

Performance range:

Direct Expansion operation: capacity up to 115 kW(R404A, Te= -8° C, T1= 0° C, RH = 85%).

Brine Operation: capacity up 160 kW(Glycol 30%, TW1= -10 °C, T1= 0 °C, RH = 85%).

Ammonia Operation: capacity up 170 kW(NH3, Te= -8 °C, T1= 0 °C, RH = 85%).

Fans Diameter:

Ø 500-560-630 mm, AC motor.

Benefits:

- Fans on top to improve working comfort.

- The upper air intake does not generate the ascending current.

blaThermoKey’s Archimede software guides you in selecting the most suitable air heat exchangers and automatically elaborates a technical data sheet. It selects the best solutions among more than 100 accessories and many possible combinations. Used for food preservation in cold rooms, fast freezing tunnels, greenhouses temperature control and other applications

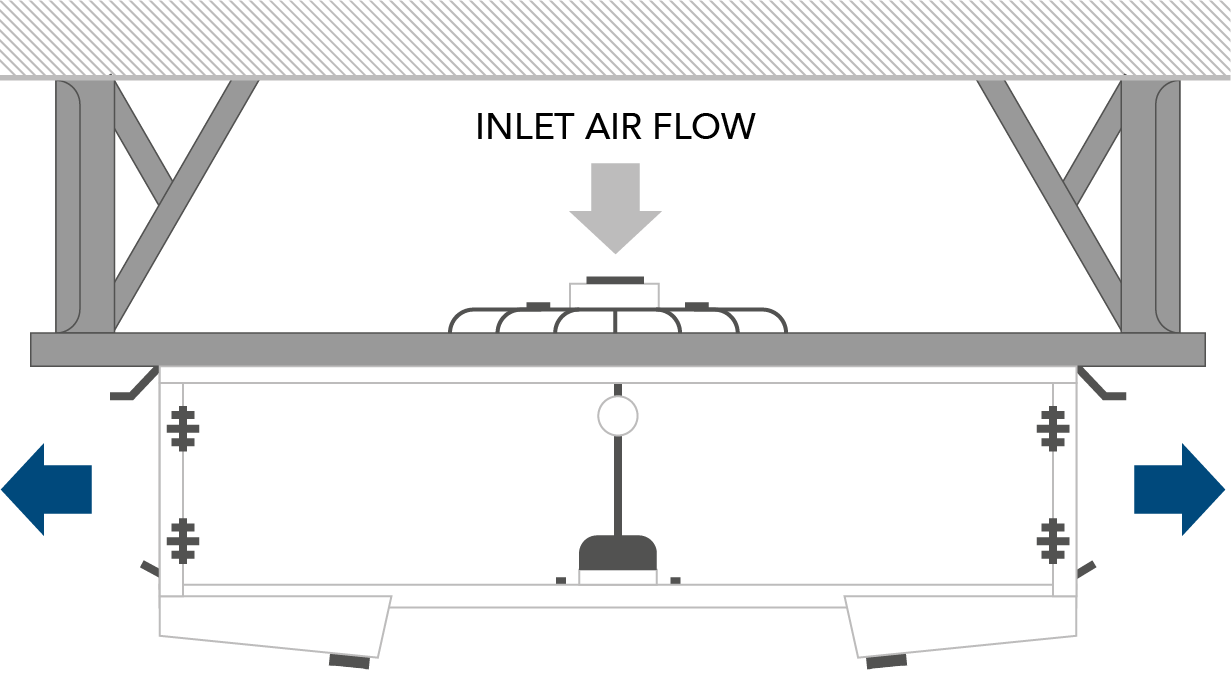

The Process Dual Flow unit coolers, with on top fans, are used in processing rooms to substantially improve comfort in the working area. Indeed this solution using upper ceiling suction (grey arrow), allows the distribution of the air without generating ascending current and also reducing the sound level of the installed unit.

- Unit Cooler brochure

- IG MANUAL - GENERAL INSTRUCTIONS FOR SAFE USE

- IM MANUAL - INSTRUCTIONS FOR HANDLING AND UNPACKING

- TC MANUAL - INSTRUCTION AND TECHNICAL SPECIFICATIONS

- IS MANUAL - SPECIFIC USE AND MAINTENANCE INSTRUCTIONS