ThermoKey’s innovative Modular Dry Cooler is designed to deliver maximum energy efficiency, operational continuity, high flexibility, and scalability — all while ensuring outstanding performance and reducing transport and management costs.

Performance range

Capacity from 200 kW (single module) to 1000 kW (5 modules in a row).

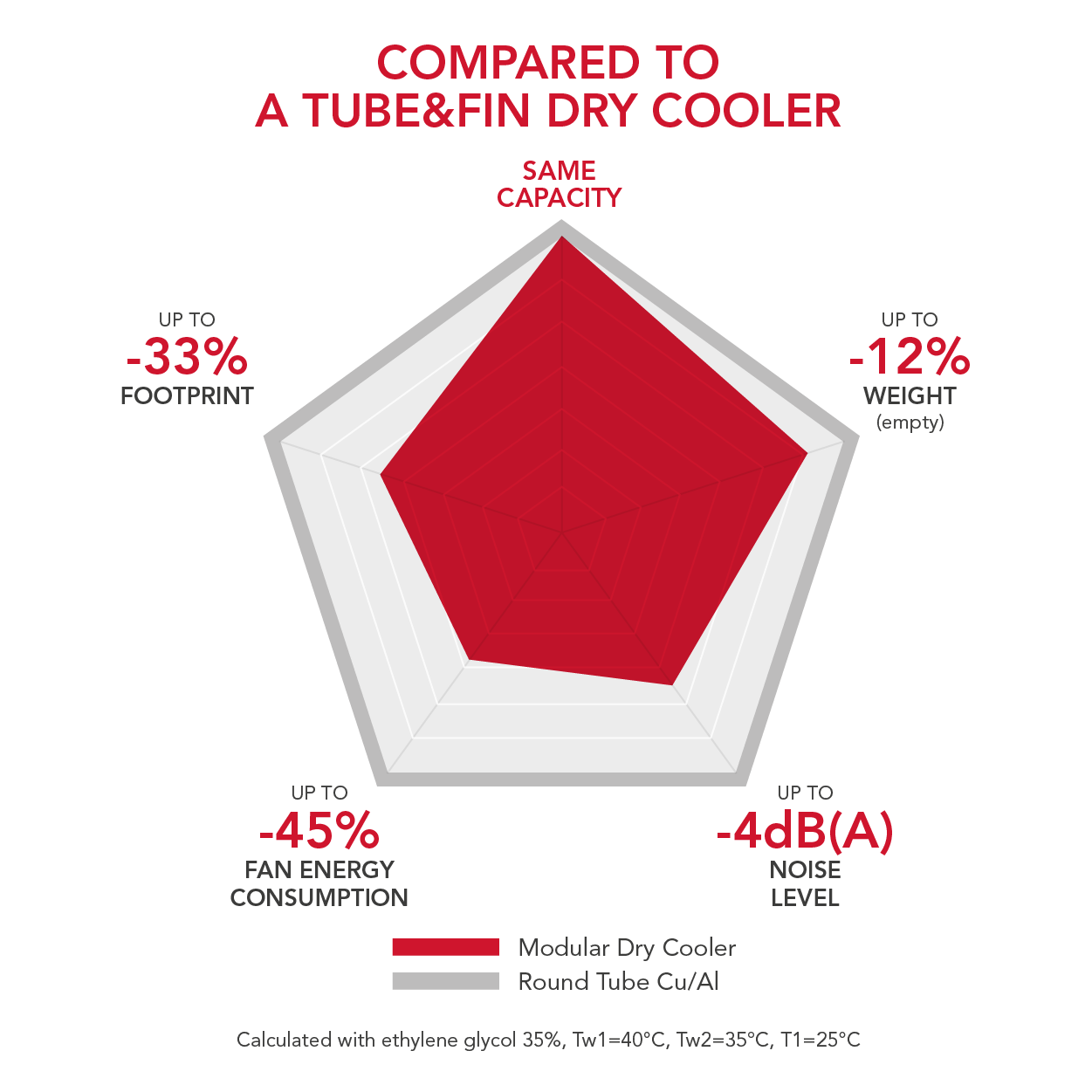

Calculated with ethylene glycol 35%, Tw1=40°C, Tw2=35°C, T1=25°C.

Fans

Diameter Ø 800, 910, 1000 mm (AC/EC motor)

Surface treatments

TK Pro, Electrofin, PolAl MC

Main advantages

- High energy efficiency

- Long-term reliability

- Operational continuity

- Power scalability and redundancy

- Easy and quick maintenance and core cleaning

- Low noise level

- High internal corrosion resistance

- Minimal footprint, size and weight

- Low transport and installation costs

- Low carbon footprint

- New header for low pressure drops

- Only 2 inlet, 2 outlet connections

Patent pending

The new ThermoKey Modular Dry Cooler has two filed patents with several topics.

Flexible configuration

ThermoKey’s Modular Dry Cooler is designed for high efficiency and maximum flexibility. Each module includes 4 vertical microchannel heat exchanger (MCHX) cores and 2 top-mounted fans, ensuring optimal airflow and thermal performance.

To improve space management and increase heat transfer efficiency, the piping and manifold system is strategically positioned at the bottom of the unit. This smart configuration not only enhances performance but also simplifies integration into various system layouts.

The Modular Dry Cooler is highly customizable, with configurations ranging from 1 to 5 modules, and offers a wide range of accessories, electrical components, and anti-corrosion surface treatments. This adaptability makes it ideal for a variety of industrial cooling, HVAC, and data center applications.

Standard configurations:

- Container: 2,5 m height x 5 modules = 2600 kg

- Super Jumbo: 2,8 m height x 5 modules = 3050 kg

Scalability and redundancy for Data Center cooling

The Modular Dry Cooler is specifically engineered to meet the critical demands of data centers and IT cooling systems, where operational criteria are non-negotiable.

- High energy efficiency

- Operational continuity

- Long-term reliability performances

- High Redundancy

Thanks to the modular design, it’s possible to expand the capacity to meet growing demand, integrating modules in series or in parallel. The manual valve and flexible connectors, and the compact footprint with low weight, allow an easy power expansion, without service interruption and reduced installation costs.

The advanced microchannel heat exchangers ensure superior heat transfer efficiency with lower air pressure drops, directly contributing to reduced fan energy consumption up to -45%, improving the PUE (Power Usage Effectiveness) index.

Modular architecture enables scalable capacity expansion and N+1 or N+2 redundancy configurations, aligning with higher Tier data center requirements.

Operational continuity

The Modular Dry Cooler is engineered to ensure no service interruption, even during maintenance.

In the event of a leak or maintenance requirement, the Hot Swappable design combined with the manual valve system allows each half-module to be easily isolated. This enables fast and safe microchannel core replacement or servicing without shutting down the entire unit — guaranteeing continuous system operation and maximum uptime, even during critical maintenance activities.

No specialized technical training is needed, making the process both simple and cost-effective. Additionally, each module includes a dedicated access window for internal cleaning, eliminating the need to disassemble the fan section as required in traditional round tube coil systems.

Quick maintenance process

High corrosion resistance

Compared to traditional solutions with copper tubes and aluminum fins, microchannel heat exchangers built entirely in aluminum alloys significantly reduce galvanic corrosion. This key advantage not only ensures a longer lifespan but also delivers superior performance throughout the heat exchangers’ operational life, thanks to the optimized contact between fins and tubes.

Low noise level

The use of MCHXs in an optimized configuration ensures very low air pressure drops and high airflow uniformity, which significantly improve aerodynamic efficiency. This setup reduces fan power consumption up to -30%, leading to a noise reduction of up to -4 dB(A).

Low installation and transport costs

The unit offers a highly efficient approach to transport and installation, especially in projects with logistical constraints. By dividing total capacity into compact modules and leveraging the advantages of microchannel technology, it is possible to achieve the same cooling output as larger round-tube units with significantly reduced size and weight.

Compared to traditional round tube technology, the Modular Dry Cooler offers up to:

- -33% footprint

- -20% weight on the roof

- -40% installation costs

- -15% transportation cost

Two complete units 5 modules each (delivering a total of 2000 kW) can fit inside a single 40ft container—maximizing the transportable capacity.